On a Saturday in late summer 2020, Health System Physical Plant Director Derek Wilson received a call just before noon from Cheryl Wagner, chief of staff with the UVA Office of the Vice President of Research.

She was working on the University’s effort to set up a saliva testing lab in order to scale up its COVID testing capabilities for the fall and spring semesters.

“She explained what was needed to get started and asked could we begin work in the lab [right away],” explained Wilson. “I made some calls. [HSPP Renovations Carpenter Supervisor] Todd Stroupe and his team responded and were in the lab working by 3 p.m.”

The project involved the transformation of a former billing office in the West Complex into what would become the UVA Be SAFE saliva testing lab, which would eventually process as many as 3,500 saliva samples a day.

The HSPP Renovations team – including carpenters and electricians – worked around the clock on the project that was completed in just a few weeks. HSPP Zone 2 Maintenance Supervisor Dudley Green and his crew of electricians also assisted to ensure the project was finished on time.

“It was a huge team effort,” said Wilson. “[HSPP Construction Project Manager] John Hennis and I worked continuously with School of Medicine researcher Jitendra Gautam, who probably worked 20 hours a day on it himself.”

The only available location for the lab did not provide the emergency power needed to serve the specialized testing equipment but the Office of the University Building Official worked closely and quickly with Facilities Management staff, paving the way for HSPP Renovations Zone Maintenance Supervisor Dean Lackey and his team of electricians to provide a main feed from an adjoining location.

The Automation Services team – including Tony Bruno, David Wright, AJ Conner and Jairemy Martin –installed a building automation panel in the space to provide the required temperature monitoring of the laboratory freezers. The team responded quickly, installing and commissioning the monitoring equipment over the course of a weekend.

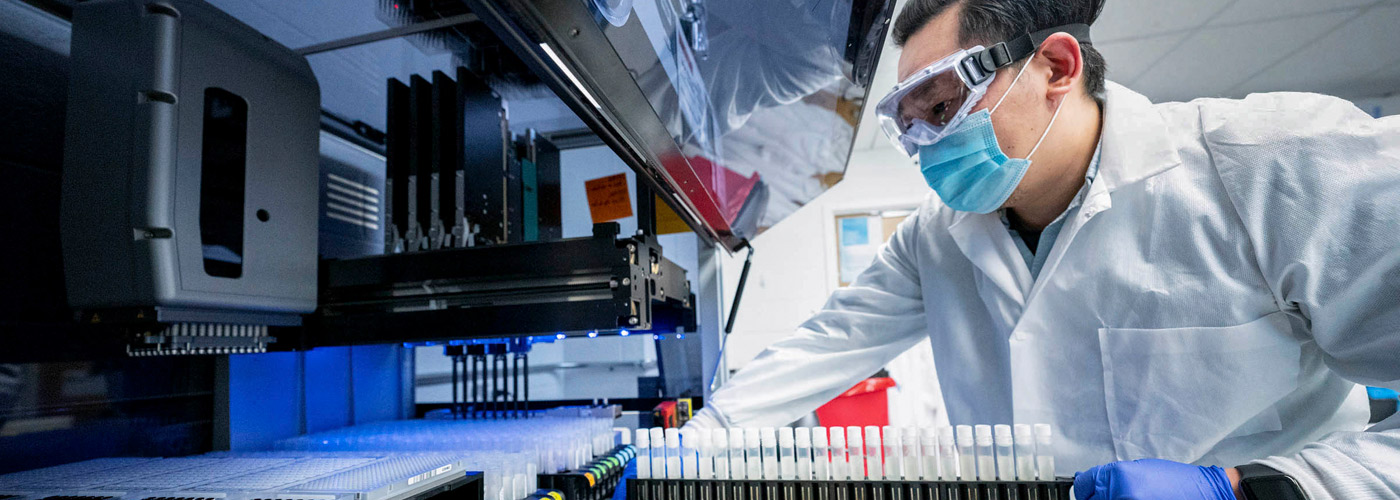

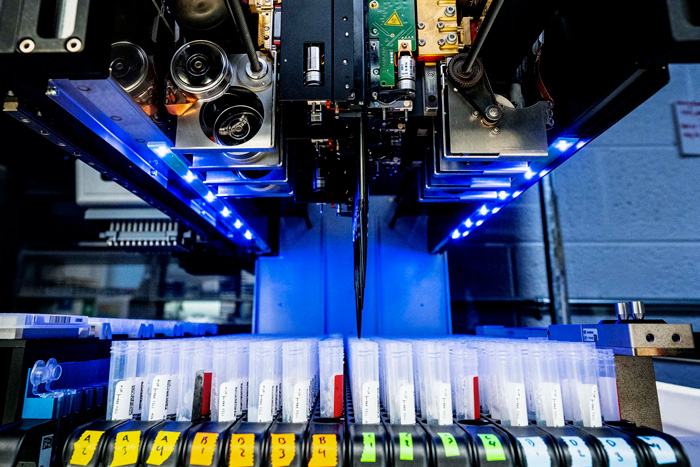

As the renovation neared completion, UVA assistant biology professor John Campbell and his neuroscience lab’s team then focused on moving their automated liquid-handling robot that had been located in Gilmer Hall into the West Complex. The robot played a central role in the lab’s discoveries about the digestive, cardiovascular and immune systems, but would soon be reprogrammed to process the saliva samples for COVID testing.

Teams helped transform multiple locations around Grounds into Be SAFE Saliva Testing Sites, which served the UVA community throughout the fall 2020 and spring 2021 semesters (Photo by Sanjay Suchak / University Communications). The User Experience & Engagement team designed the Be SAFE signage, which was printed and installed by the Sign Shop, who also fabricated and installed plexiglass barriers in all of the testing sites (Video still by University Communications).

The team had hired a group of specialized movers to ensure the robot would be transported out of Gilmer Hall before that building was closed off for its renovation, but when those movers failed to show up, four McCormick Zone Maintenance employees stepped in to help. Todd Swanson, Doug Matthews, Justin Bernard and Kenny Graham successfully moved the delicate, 600-pound robot out of the building, and it was relocated to the West Complex a few weeks later where it operated six days a week throughout the spring 2021 semester, more than doubling the saliva lab’s daily testing capacity.

In addition to the setup of the lab, additional Facilities Management and UVA teams helped transform multiple locations around Grounds into Be SAFE saliva testing sites. The Office of the University Building Official helped with permitting and occupancy of the saliva testing site at the Central Grounds Garage, one of the main saliva collection sites located on the top floor of the garage. Newcomb Zone Maintenance electricians installed additional power outlets and network cable conduit within the space as well as temporary heat during some of the winter months. The User Experience & Engagement team designed the Be SAFE signage, which was printed and installed by the Sign Shop, who also fabricated and installed plexiglass barriers in all of the testing sites.